Strategia - Edistämme kestävää materiaalien käsittelyä, luomme lisäarvoa osakkeenomistajillemme sekä autamme asiakkaitamme parantamaan turvallisuutta, vastuullisuutta ja tuottavuutta.

Toimialat - Kalmar tarjoaa markkinoiden laajimman valikoiman raskaita materiaalinkäsittelylaitteita ja -palveluja satamien, terminaalien, jakelukeskusten, valmistusteollisuuden ja raskaan logistiikan tarpeisiin.

Toimittajat - Jatkuva kehitys kaikilla alueilla on Kalmarin toimitusketjun menestyksen avain.

Laitteet - Tarjontaamme kuuluvat huippulaadukkaat terminaalitraktorit, konttikurottajat, haarukkatrukit, tyhjien konttien käsittelylaitteet, konttilukit ja tarttujat.

Vara-osat ja palvelut - Maailmanlaajuisen yli 1 300 huoltoteknikon verkostomme sekä laajan varaosa-, huolto- ja elinkaaripalveluvalikoimamme avulla varmistamme lastinkäsittelylaitteiden käyttöajan koko niiden elinkaaren ajan.

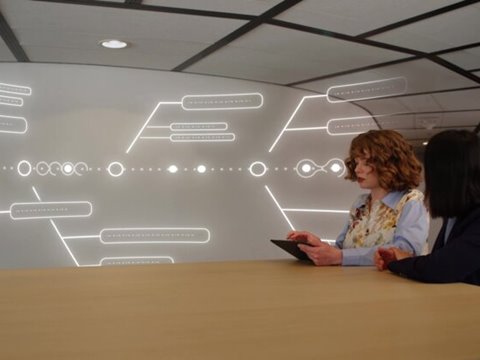

Automaatio ja robotiikka - Automaatio- ja robotiikkaratkaisujemme avulla toiminnan tehokkuus saadaan maksimoitua niin, että myös turvallisuus ja vastuullisuus paranevat.